Nova aetas industriae autocineticae novae energiae duplicem munus gerit, transformationis industrialis et meliorationis atque tutelae ambitus atmosphaerici, quod magnopere impellit progressionem industrialem filorum altae tensionis aliorumque accessionum conexarum pro vehiculis electricis, et fabri filorum et corpora certificationis magnam energiam in investigationem et progressionem filorum altae tensionis pro vehiculis electricis impenderunt. Fila altae tensionis pro vehiculis electricis requisita altae efficaciae in omnibus aspectibus habent, et requisitis normae RoHSb, requisitis normae UL94V-0 ignifugae gradus, et efficaciae mollis satisfacere debent. Haec dissertatio materiam et technologiam praeparationis filorum altae tensionis pro vehiculis electricis introducit.

1. Materia funis altae tensionis

(1) Materia conductoris funis

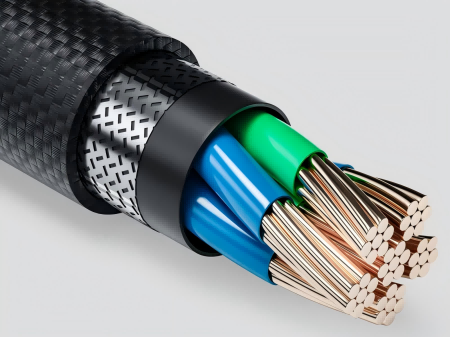

In praesenti, duae materiae principales strati conductoris funis exstant: cuprum et aluminium. Paucae societates putant nucleum aluminii sumptus productionis magnopere minuere posse, addito cuprum, ferrum, magnesium, silicium, aliaque elementa in fundamento materiae aluminii puri, per processus speciales ut synthesis et tractationem recoquendi, conductivitatem electricam, facultatem flexionis, et resistentiam corrosionis funis augere, ut requisitis eandem capacitatis oneris satisfaciat, eundem effectum ac conductores nuclei cuprei vel etiam meliorem consequatur. Ita sumptus productionis magnopere conservantur. Attamen pleraeque societates adhuc cuprum ut materiam principalem strati conductoris habent, primum, resistentia cupri humilis est, deinde pleraque efficacia cupri melior quam aluminii in eodem gradu, ut magna capacitas portandi currentem, humilis amissio tensionis, humilis consumptio energiae, et magna firmitas. In praesenti, selectio conductorum plerumque utitur norma nationali sex conductorum molium (elongatio unius fili cuprei maior quam 25% esse debet, diameter monofilamenti minor quam 0.30) ut mollitiem et duritiam monofilamenti cuprei confirment. Tabula 1 normas enumerat quae pro materiis conductoribus cupreis vulgo adhibitis servandae sunt.

(2) Materiae stratarum insulantium funium

Ambitus internus vehiculorum electricorum complexus est. In delectu materiarum insulantium, ex una parte, ut usus tutus strati insulantis curetur, ex altera parte, quantum fieri potest, materiae faciles ad usum et late adhibitae eligendae sunt. Hodie, materiae insulantes vulgo adhibitae sunt polyvinylchloridum (PVC).polyethylene reticulatum (XLPE), gummi siliconis, elastomerus thermoplasticus (TPE), etc., et proprietates earum principales in Tabula II monstrantur.

Inter ea, PVC plumbum continet, sed Directiva RoHS usum plumbi, hydrargyri, cadmii, chromii hexvalentis, polybrominati diphenyletheris (PBDE) et polybrominati biphenylorum (PBB) aliarumque substantiarum noxiarum vetat, itaque annis proximis PVC a XLPE, gummi siliconico, TPE aliisque materiis amicabilibus ambienti substitutum est.

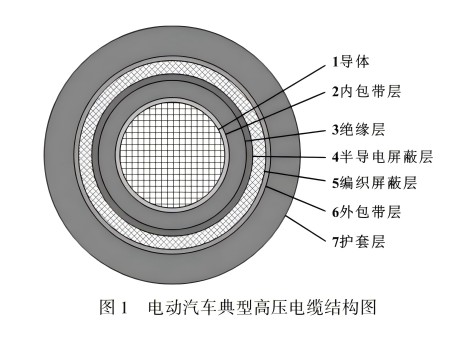

(3) Materia strati tegumenti funis

Stratum tegumentum in duas partes dividitur: stratum tegumentum semiconductivum et stratum tegumentum textum. Resistivitas voluminis materiae tegumenti semiconductivae ad 20°C et 90°C et post senescentem est index technicus magni momenti ad materiam tegumenti metiendam, qui indirecte vitam utilem funis altae tensionis determinat. Materiae tegumenti semiconductivae communes includunt gummi ethylenum-propylenum (EPR), polyvinylchloridum (PVC), et...polyethylenum (PE)Materiae fundatae. Si materia prima nullum commodum habet et gradus qualitatis brevi tempore emendari non potest, instituta investigationis scientificae et fabri materiarum funium in investigatione technologiae processus et proportionis formulae materiae protegentis intendunt, et innovationem in proportione compositionis materiae protegentis quaerunt ut efficaciam generalem funis augeant.

2. Processus praeparationis funis altae tensionis

(1) Technologia filorum conductorum

Processus fundamentalis funiculorum iam diu elaboratus est, itaque propriae specificationes normae in industria et negotiis exstant. In processu tractionis filorum, secundum modum evolvendi fili singularis, apparatus evolvendi in machinas evolvendi evolvendi, machinas evolvendi evolvendi et evolvendi/evolvendi dividi potest. Propter altam temperaturam crystallizationis conductoris cupri, temperatura et tempus recoctionis longiores sunt, aptum est apparatum evolvendi evolvendi adhibere ad tractionem continuam et tractionem continuam monofilamenti perficiendam ad elongationem et fracturam evolvendi fili emendandam. Hodie, funis polyethylene reticulatus (XLPE) funem chartaceum olei inter gradus tensionis 1 et 500kV omnino substituit. Duo processus communes formationis conductorum pro conductoribus XLPE sunt: compactio circularis et torsio filorum. Ex una parte, nucleus filorum vitare potest altam temperaturam et pressionem in tubo reticulato ut materiam suam protectivam et materiam insulationis in spatium filorum premat et iacturam efficiat; Ex altera parte, etiam infiltrationem aquae secundum directionem conductoris impedire potest ut operatio tuta funis praestetur. Ipse conductor cupreus structuram concentricam funiculi habet, quae plerumque a machina funiculi ordinaria, machina funiculi furcae, etc. producitur. Comparatus cum processu compactionis circularis, formationem rotundam funiculi conductoris praestare potest.

(2) Processus productionis insulationis funium XLPE

Ad productionem funis XLPE altae tensionis, nexus sicca catenaria (CCV) et nexus sicca verticalis (VCV) duo processus formationis sunt.

(3) Processus extrusionis

Antehac, fabri funium secundarium processum extrusionis ad nucleum insulationis funium producendum utebantur, primo gradu simul extrudendo scutum conductoris et stratum insulationis, deinde reticulato et contorto in alveum funium, per aliquod tempus posito, deinde extrudendo scutum insulationis. Decennio 1970, processus extrusionis trium stratorum 1+2 in nucleo filorum insulatorum apparuit, quo permiserunt ut scutum et insulatio interna et externa uno processu perficiantur. Processus primum scutum conductoris extrudit, post breve spatium (2~5m), deinde insulationem et scutum insulationis in scuto conductoris simul extrudit. Attamen, duae primae methodi magna incommoda habent, itaque exeunte decennio 1990, fabri instrumentorum productionis funium processum productionis co-extrusionis trium stratorum introduxerunt, quo scutum conductoris, insulationem et scutum insulationis simul extrudebantur. Abhinc annos paucos, nationes externae etiam novum caput cylindricum extruderis et laminam reticulatam curvatam inceperunt, quae, pressione fluxus in cavitate capitis cochlearum aequata, accumulationem materiae minuunt, tempus productionis continuum extendunt, et mutationes continuas specificationum designii capitis substituunt, quae etiam sumptus inoperabiles magnopere servare et efficientiam augere possunt.

3. Conclusio

Vehicula novae energiae bonas progressionis spes et mercatum ingens habent, seriem productorum funium altae tensionis cum magna capacitate oneris, alta resistentia temperaturae, effectu protectionis electromagneticae, resistentia flexionis, flexibilitate, longa vita operativa, aliisque praestantibus functionibus in productionem et mercatum occupandum requirunt. Materia funium altae tensionis vehiculorum electricorum et processus praeparationis latas progressionis spes habent. Vehicula electrica sine funibus altae tensionis efficientiam productionis augere et securitatem usus praestare non possunt.

Tempus publicationis: XXIII Augusti, MMXXIV